Recommend

Remove File

Remove document <span id="remove-document-name"></span> from <span id="remove-cart-name"></span>?

Capital intensive automobile manufacturing plants produce a large volume of high quality vehicles. But they also must be flexible to handle a wide variety of rapidly changing models. Only the most versatile, reliable, and ergonomic equipment is used in modern automotive plants – and that is exactly where you will find Conductix-Wampfler products.

In the early stages of manufacture, electric overhead traveling cranes ( EOT) handle steel coils, foundry parts, and raw materials. Transfer cars take tooling and materials to and from the presses in the press shop. Components are transferred by Electrified Monorail Systems ( EMS) to the body shop, where “bodies in white” (BIW) take shape. EMS or powered skid conveyors move raw car bodies to the paint shop. Large scale Automated Storage and Retrieval Systems ( AS/RS) provide a storage buffer for just-in-time sequencing of assemblies. Automated guided vehicles ( AGV) and rail guided vehicles (RGV) are used at the drive train pre-assembly lines and at the “marriage line” (chassis decking). In final assembly, EMS and conveyors operate under the ceiling, while skillet lines work at floor level. Assembly workers need workstations, hoists, tool balancers, and tool transports for required tools, as well as electric and pneumatic power to operate them.

We offer a wide range of energy and data transmission solutions to work alongside the full spectrum of automotive manufacturing processes. Whether it is to provide power and data for cranes, electrified monorail systems, conveyors, transfer cars, skillet systems, or assembly tools, Conductix-Wampfler has the right solutions for the need.

Conductor Rails–power EOT crane runways, electrified monorail systems ( EMS), transfer cars, flexible conveyor systems and large-scale AS/RS.

Cable Festoon Systems – manage cables for EOT crane bridge travel, AS/RS systems and manage assembly line electric and compressed air lines for power tools.

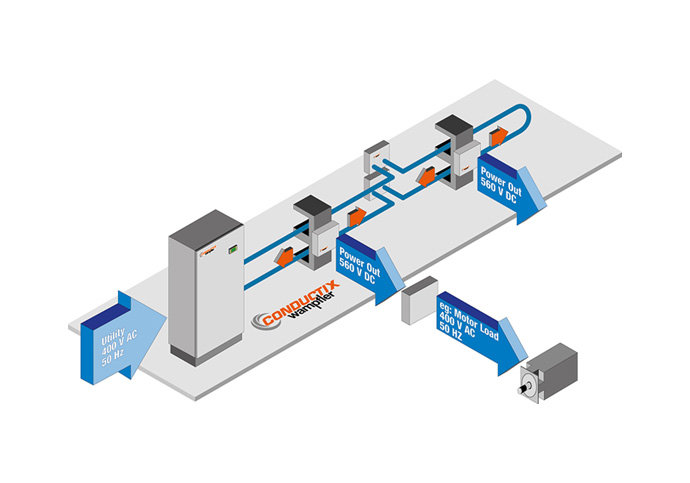

Inductive Power Transfer (IPT®) – provides contactless power for transfer cars, skillet lines with lift tables, Automated Guided Vehicles ( AGV) or Rail Guided Vehicles (RGV).

Electric/Compressed Air Systems, Tool Transports, and Balancers – to increase productivity and safety on assembly lines, our systems provide easy access to assembly line tools, constant electric and compressed air for power and ergonomic assists.

Spring-Driven Cable Reels – provide external 12V energy supply for the vehicle testing and for different types of transfer cars.

High-speed Cellular Buffers – to cushion impacts on lift stations and turntables.

Jay Radio Remote Controls – offer a safe way of operating or monitoring machines from a distance. The comprehensive range of industrial and safety radio remote controls offers countless solutions to adapt to an extensive number of automotive applications.

Reference Report

[REF9000-0006-E]

Application

Electrified Monorail System

Operator

Mitsubishi Motors, Adelaide, Australia

Product

IPT® (Inductive Power Transfer)

Track length

500 m

Number of vehicles

17

Specific features

Energy- and Data supply inductive

Generally the basic function of Rail systems is the same as that of other Inductive Power Transfer systems. But there are some additional or specific aspects to consider.

Because vehicles are usually rail guided here and an elevated installation of the cable is possible it becomes also possible to use E-shaped pickups.

In applications with traveling track segments, i.e. switches in electric monorail systems (EMS), the experience with inductive power transfer can be used to supply such track segments inductively with energy.

Naturally contactless, inductive power transfer systems can also replace other conventional solutions, as cable chains or conductor rails in skillet lines, skids or in transfer cars if there are certain requirements on the solution, for example if voltage arcs at rail ends shall be avoided or if the access for maintenance underneath skillet platforms is very limited, environmental demands on the power transfer solution are high, etc.