Ports

Throughout recorded history, cargo ports have played a vital role in the development of economies and countries. The importing and exporting of many types of goods are handled by countless port facilities around the globe, from small river ports to specialized sea ports that handle bulk materials, break bulk, special cargo, Ro-Ro (roll-on/roll-off) or containers. Depending on the type of goods handled by a given port, dedicated material handling machines such as cranes, loaders, and unloaders efficiently manage logistics within the port’s operations. Often operating 24 / 7 / 365, this equipment needs to be extremely reliable and able to operate in very harsh environments. Increasing global trade has driven ever increasing demands for faster, more reliable, and better performing port equipment components. Energy and data transmission systems play a crucial role in providing safe, reliable, and efficient port operations. Due to increasing requirements for “green” ports and environmental friendly handling facilities, operators will continue to convert combustion engines to electric drives. In addition, more and more ports are providing shore power for docked vessels to further reduce emissions.

With decades of experience in this industry, Conductix-Wampfler offers customized solutions for port cranes and material handling equipment and machinery. Conductix-Wampfler offers a large network of sales and engineering facilities close to our customers. Turnkey solutions and a strong after sales and servicing team support our customers in their global activities.

Motor-Driven Reels – the reliable and practical solution to manage cables for the long travel of cranes and ship loaders/un-loaders. We supply customized cable reels with magnetic clutches or frequency controlled drive units. Motorized reels are used to convert traditionally diesel-driven mobile harbor cranes (MHC) to electric power or as one more specialized solution to provide “ E-Shore” power to connect ships to an onshore power source, which allow them to shut down their engines.

Cable Festoon Systems – motorized and non-motorized festoon systems manage cables for crane cross travel, traditional but extremely reliable and durable.

Conductor Rails – efficiently provide power for crane cross travel - with the addition of dedicated rails for multiplexed data transfer. Conductor bars also can be mounted beneath the wharf to carry medium distribution voltages from 5 kV to 13.8 kV for long crane travel.

Energy Guiding Chains – manage multiple power and control cables for crane cross travel on cranes.

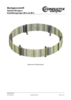

Slip Rings and Fiber Optic Transmitters – provide uninterrupted energy and data transmission for all rotating machines, including harbor cranes and cable reels.

Cable Protection Systems – the trench cover systems Trenchguard or the new CoverZIP system guaranty a safe cable handling and cable protection.

Spring-Driven Cable Reels – are used for portable power in maintenance areas.

E-RTGTM Container Kran

Anlagenbeschreibung

E-RTGTM Container Kran

Land

China

Ort

Yingkhou

Vertretung

Conductix-Wampfler [CN]

Betreiber

Yingkhou New Century Container Terminal [NCCT]

Technische Anforderung[en]

Elektrifizierung von 24 Container-Blöcken mit RTG Nutzung [E-RTGTM]

Produkt[e]

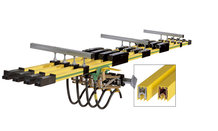

- Schleifleitung, Programm 0813 SinglePowerLine

- 20 E-RTGTM Drive-In Units 4P-1

Anzahl Pole

3 + PE

Stromabnehmer

Doppelstromabnehmer

Einspeisung

Endeinspeisung

Strom

1.000 A

Spannung

440 V

Länge [System]

6 km

Systemverlauf

Linear

Verfahrweg [Verbraucher]

250 m pro Block

Verfahrgeschwindigkeit [Verbraucher]

130 m/min

Umgebungsbedingung[en]

Container-Hafen [Seeluft]

Relevant Products

Single PowerLine 0813

Additional information

Einzelpolige Schleifleitung für den vorzugsweise geraden Bahnverlauf.

Wichtige Merkmale

- Hohe Verfügbarkeit auch im robusten Einsatzfeld durch robusten Aufbau und unterschiedlicher Leitungswerkstoffe

- Sicherheit für Mensch und Maschine durch Isolation der Einzelpole

- Einfache und exakte Montage mit kombinierbaren mehrpoligen Schienenhaltern (3, 4 und 5 Pole)

- Unbegrenzte Polzahl auch für komplexe Anwendungen

- Kurvengängigkeit durch werkseitig lieferbare Bogensegmente

Typische Applikationen

- Krananlagen im oberen Leistungsbereich

- Seilgezogene STS Kran-Katzsysteme

- People Mover / Personentransport-Systeme

- Sonderanlagen

Product data

Standard Einsatzdaten

- Nennstrombereiche (100% ED) [A]: 500 | 800 | 1.000 | 1.250

- Nennspannung [V]: 690

- Schienenlänge [mm]: 5.000

- Außenabmessungen (Pol) [mm]: 32,0 x 42,0

- Einsatzbereich: Innen und geschützter Außenbereich

- Bahnverlauf: vorzugsweise gerader Bahnverlauf / Kurvensegmente werkseitig möglich

Downloads

Conductix-Wampfler GmbH

Weil am Rhein

Rheinstrasse 27 + 33

79576 Weil am Rhein

Germany

Phone: +49 (0) 7621 662 0

Fax: +49 (0) 7621 662 144

www.conductix.de

info.de@conductix.com

Supplier Self Disclosure General Terms and Conditions of Delivery, Payment and Installation General Terms and Conditions of Purchasing Conductix-Wampfler GmbH Environmental Statement 2020 Conductix-Wampfler GmbH

Conductix-Wampfler Automation GmbH

Potsdam

Handelshof 16 A

14478 Potsdam

Germany

Phone: +49 (0) 331 887344 - 0

www.conductix.de

info.potsdam@conductix.com

- 2 more clicks for privacy: By clicking here, the button becomes active and you can send your recommendation to Facebook. With the activation data will be transmitted to third parties.mit Facebook verbunden

- 2 more clicks for privacy: By clicking here, the button becomes active and you can send your recommendation to Twitter. With the activation data will be transmitted to third parties.nicht mit Twitter verbunden

![Elektrifizierung von 24 Container-Blöcken mit RTG Nutzung [E-RTG TM] E-RTGTM Container Kran](https://conductix-de-live.cxw-development.com/sites/default/files/styles/teaser-image/public/Pic_2_105_1349_1.jpg?itok=Hx5lc99O)

![Elektrifizierung von 24 Container-Blöcken mit RTG Nutzung [E-RTG TM] E-RTG TM Container Kran](https://conductix-de-live.cxw-development.com/sites/default/files/styles/teaser-image/public/Pic_3_105_1350_1.jpg?itok=QqXK9--o)